Comprehensive engineering solutions tailored to your needs

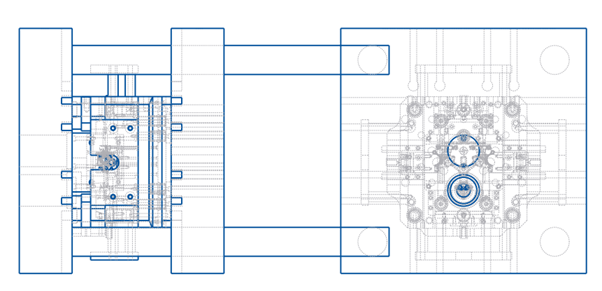

Expert mould design ensuring maximum productivity and minimum errors.

Our Design Department employs highly skilled Engineers capable of using the most advanced modelling software so that it ensures the lead time of New Product Development, mould Development and parts manufacturing and the potential for human error is also greatly reduced.

Our professional staff of Design Engineers provide you innovative ideas you need to ensure your product’s success. And Engineering assistance for New Product Development, Product design, Reverse Engineering & Manufacturing feasibility.

We have excellent Design Engineers and Tool makers for manufacturing of Tools.

The outcome are Tools that ensures Maximum Productivity, Minimum Rejection, Minimum Secondary Operations, Extended Tool Life and Ease of Maintenance throughout the life of the Tool.

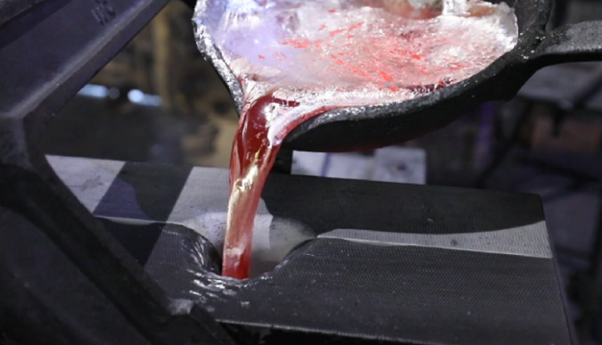

High-precision die casting with smooth surfaces and accuracy.

IKSHA Designs and Engineering is leading provider of die casting services across India. Our team of engineers, technicians, and quality control experts work together, ensuring that your product gets done right and on time.

We focus on new die casting technologies to produce complex parts with excellent dimensional accuracy and smooth cast surfaces. We can produce a casting from 3 grams to 2.5 kgs.

Precision-engineered gravity die casting tailored to requirements.

We offer precision Engineered Gravity dies and castings as per the customer requirement either with the help of drawings or from sample products.

Casting ranges we can produce from 0.050 kgs to 12 kgs.

Premium quality plastic mould parts delivered with precision.

Plastic Injection Mould Parts we offer are highly qualitative and made in confirmation with the specific norms. Material of premium quality is used in manufacturing process and we try our best to deliver our range within specific time-period.

The company is an expert in moulding engineering, commodity, and speciality plastic raw materials. This includes the Nylone6 Family inclusive of Glass filled, LDPE and HDPE, Acrylic, Nylon (GF Filled and unfilled grades), Polycarbonates, ABS (Filled and unfilled grades), Acetal / Delrin.

Understanding your requirements and project scope

Creating detailed technical specifications and plans

Engineering implementation and prototyping

Testing, validation, and final project handover

Our expert team is ready to collaborate and bring your ideas to life.

Get in Touch